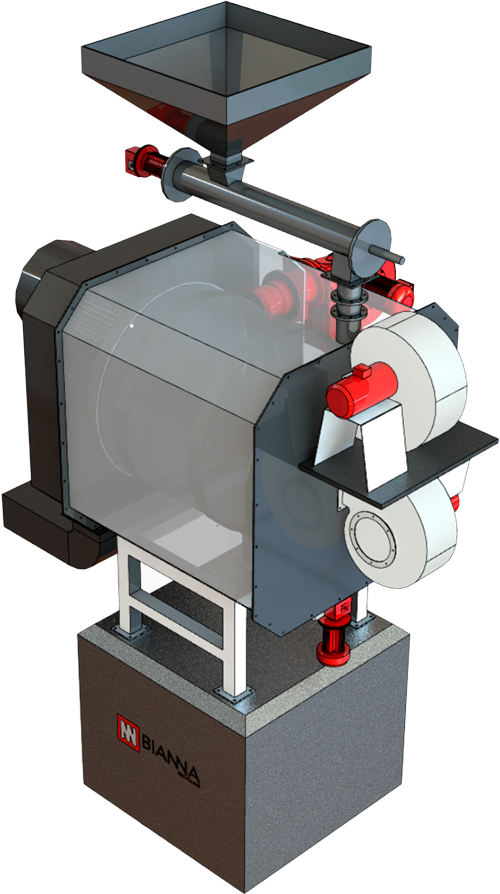

Solid waste burner

We design, manufacture and install solids burners tailored to the needs of the market. Through specific training, we support the client throughout the commissioning for optimal implementation.

ThermoValue Solutions offers a range of burners for waste and industrial processes, easy to use and maintain and ensuring optimum performance with minimal energy consumption and low emissions. For this, a A team of combustion engineers accompanies the client during the installation and commissioning process of this new technology.

SWB burners are characterized by a modular monobloc structure. In other words, all the necessary components can be combined into a single unit, which ensures an easier, faster and, above all, more flexible installation.

The SWB series of burners covers a cooking range of 1500 to 5500 kW. Thanks to a mechanical regulation cam device, they are able to accurately supply the power demanded by the material or process, guaranteeing high efficiency and stability, obtaining fuel consumption and reducing operating costs.

The operation can be “progressive in two stages” or alternatively “modulating”, both for fuels (such as waste, wood, etc.) and for gas, with the installation of a PID logic controller.

The combustion head guarantees low polluting emissions (NOx <80 mg / kWh in gas operation). Its exclusive design guarantees low noise emissions, low electrical consumption, easy use and maintenance.

All of our process burners are supervised by combustion engineers trained to provide technical assistance throughout the project, from start to commissioning.