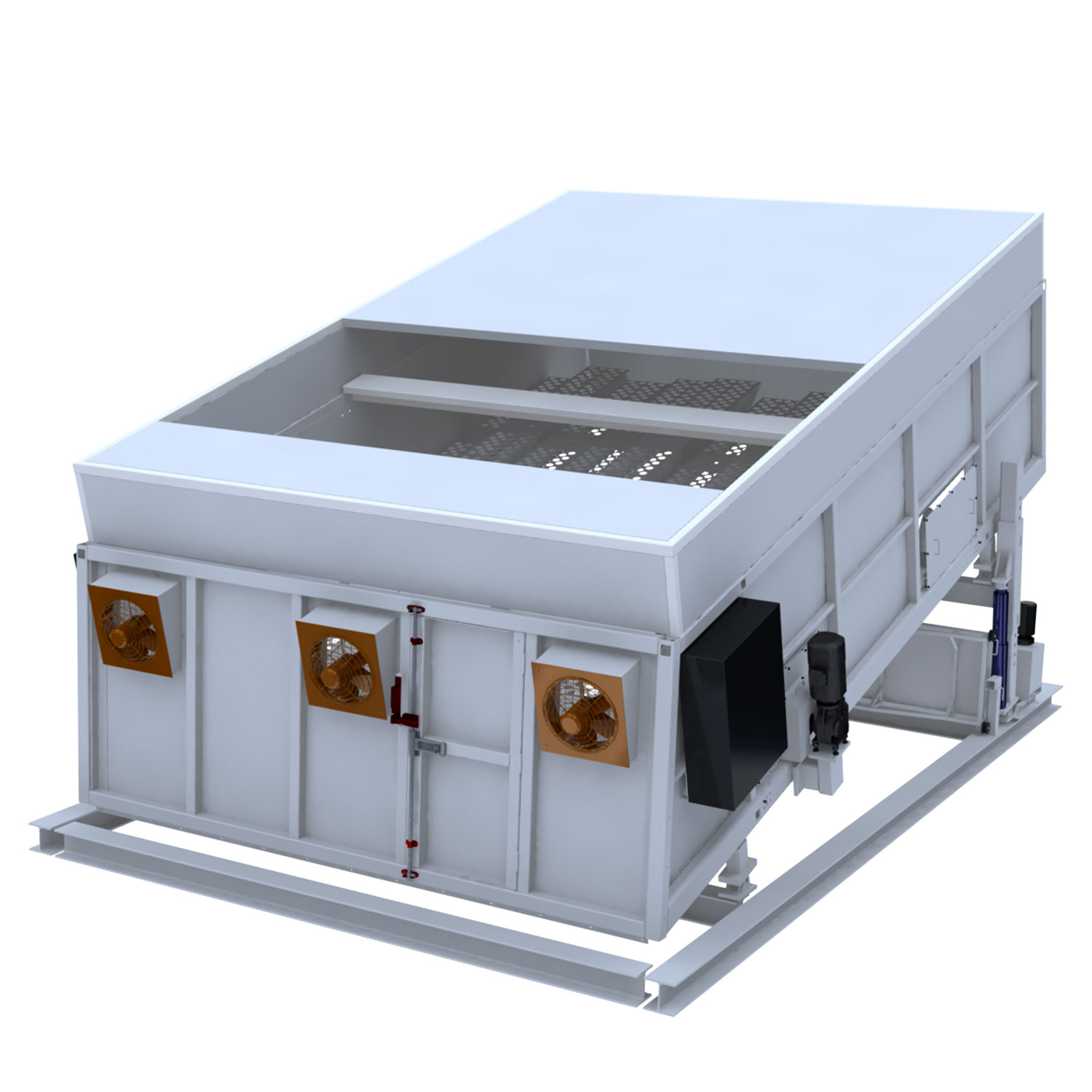

Ballistic separator

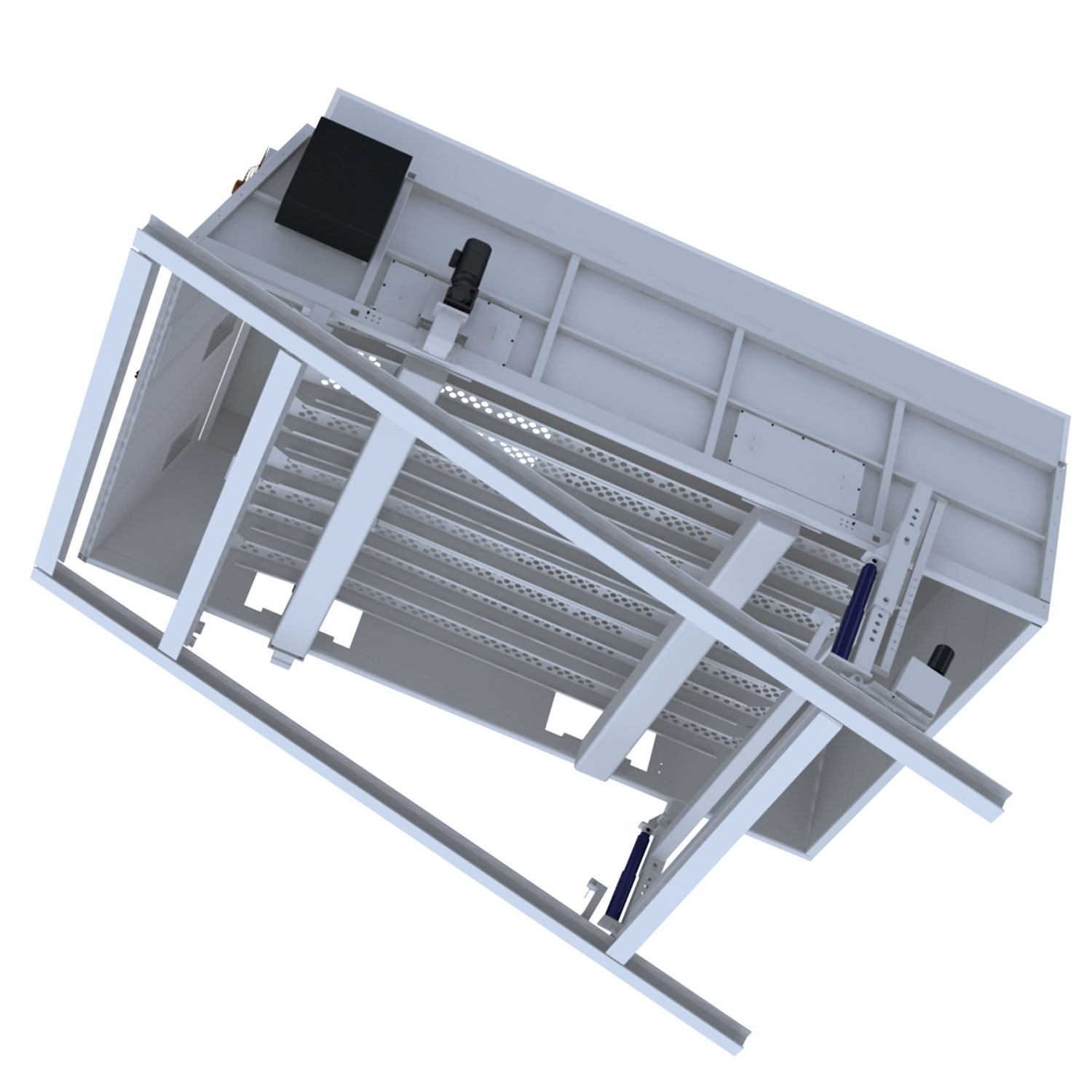

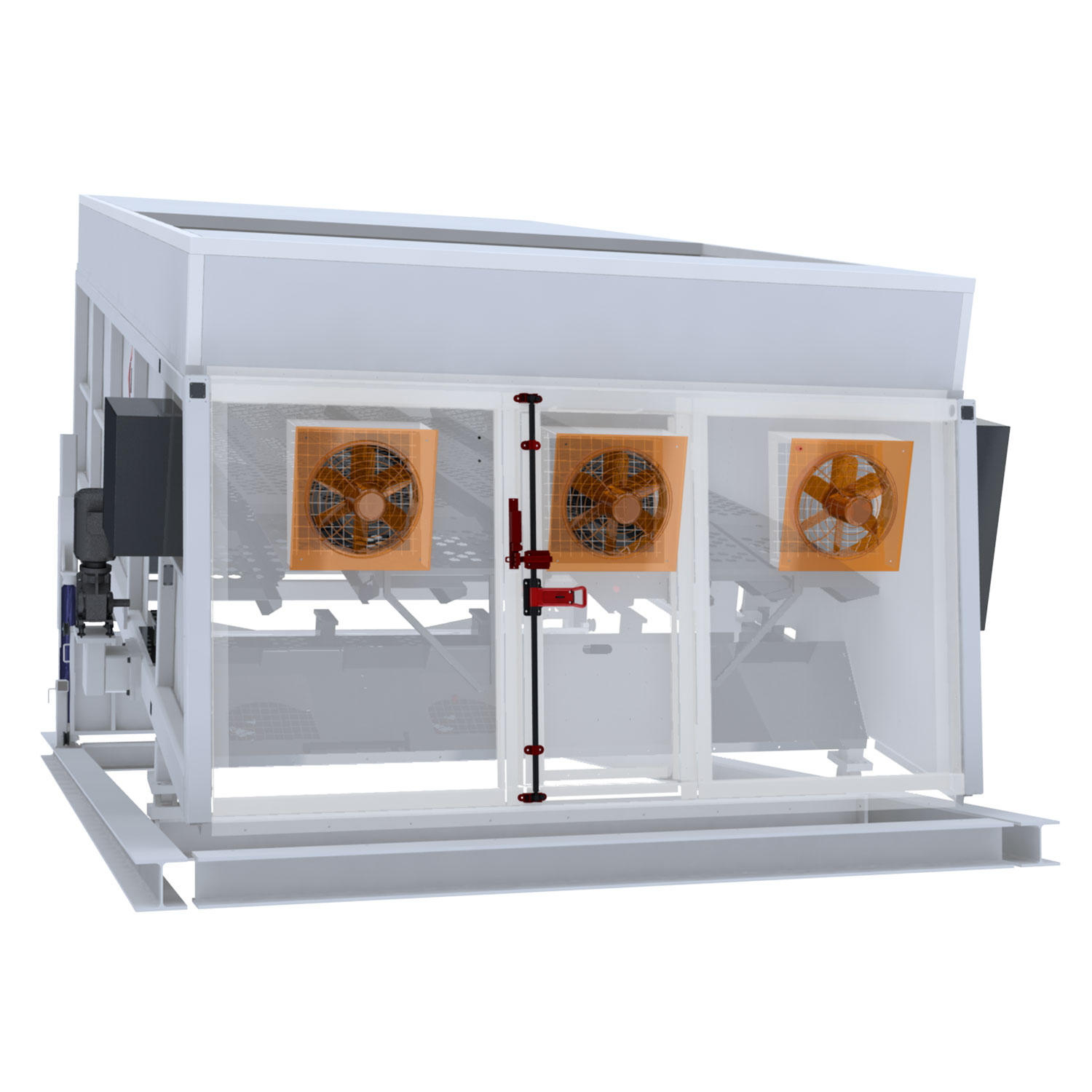

Size, density and shape: the ballistic separator is an essential equipment in the treatment line, specifically designed to separate the input solid waste depending on these three features

Widely known for their reliability and efficiency, Bianna’s wide range of ballistic separators are used in RSU, EELL and CSR plants. There is the possibility to adjust different parameters in order to adapt automatically the type of material, from the fan speed to the equipment slope.

The equipment is especially designed to make cleaning and maintenance easier, and it is supplied with different devices which make the inside of the ballistic as ergonomic and comfortable as possible.