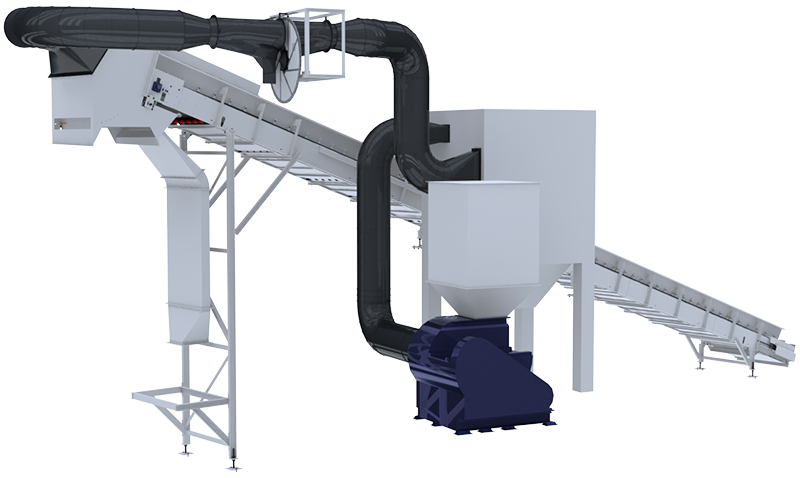

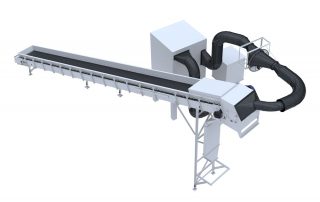

PEBD Suction system

The implementation of this system guarantees an optimal separation of the plastic film fraction

We have improved our know-how on these equipments, thanks to our pneumatic expertise, developing a highly efficient system for the recovery of PEBD plastic (low density polyethylene) which is based on:

- Hopper fitted with adjustable deflectors for the right air ducting.

- Adjustable blow nozzles.

- Alveolar valve for the suction film decantation and air separation.

- Sleeve felter for the dust elimination.

- Impulsion and suction fans.

- Galvanised steel pipelines transportation system.

We also offer customised solutions for each project, searching for a great plastic film separation and low investment costs.