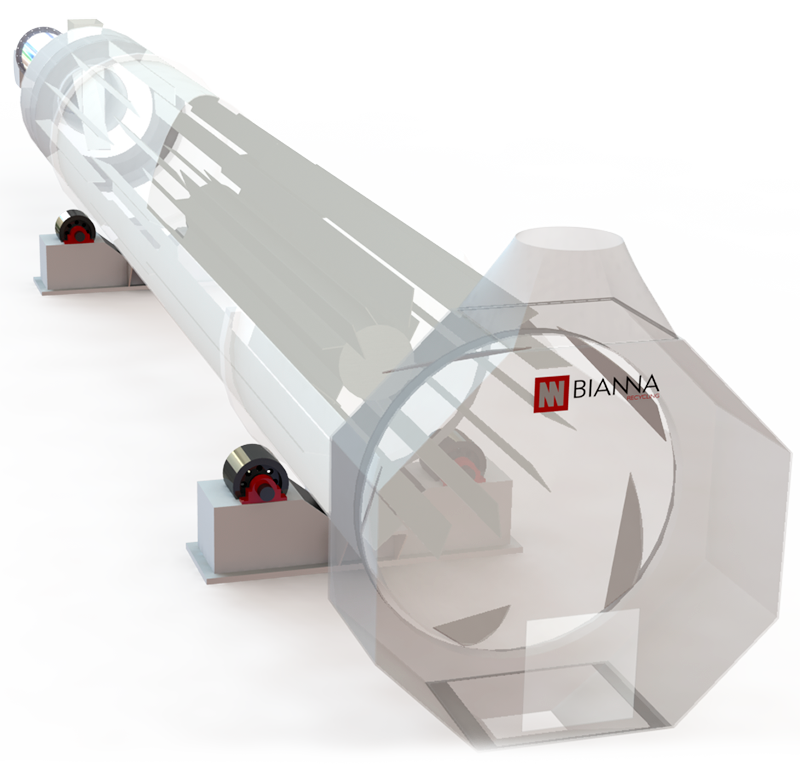

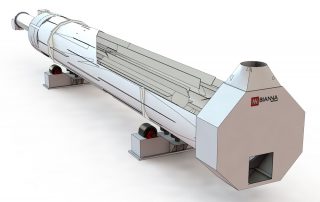

Drum dryer

Designed to be versatile with a sturdy conception. DDR drying drums are an essential part of drying lines that allows to achieve bulk mixed materials and products in controlled humidity ranges.

Dryers are an ideal choice for efficiently drying bulk solids. They can be a complete process by itself or be part of a longer thermal process. In all circumstances, this robust construction machinery is the best choice for adapting to variations in raw material.

Bianna from its ThermoValue Solutions business line, offers a series of DDR drying drums with different diameters, lengths and thicknesses depending on the application to which the equipment will be subjected: parallel or counter current rotary dryer, kind of material and quantity of moisture to evaporate in the inflow.

The equipment, manufactured with a rotary drum and installed over a 2⁰ to 4⁰ inclined plane, receives the material from the upper starting part. The material moves in the lower zone due to rotational movement and gravity. During this process, the material receives heat from the drying gas flow. The dry material is discharged into another hopper at the end of the drum.

Our DDR drying drums incorporate the latest security systems and interior access specifically designed to facilitate cleaning and maintenance.