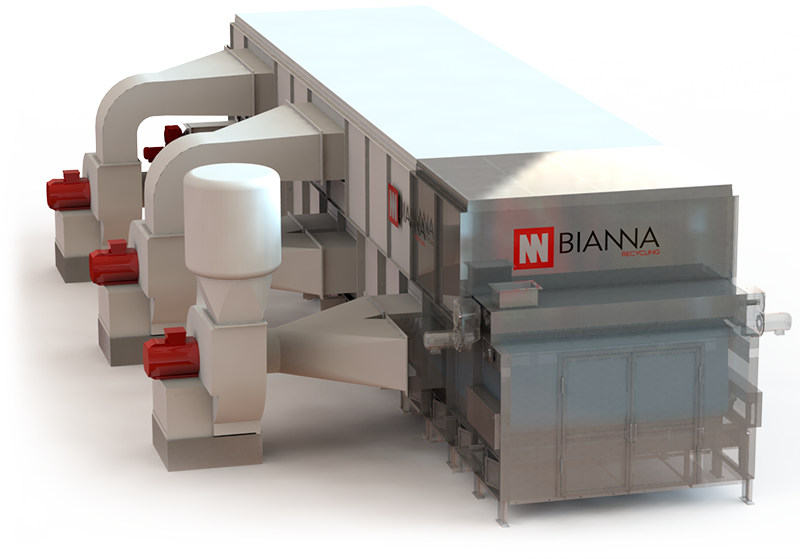

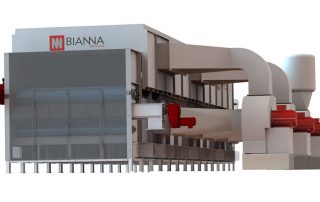

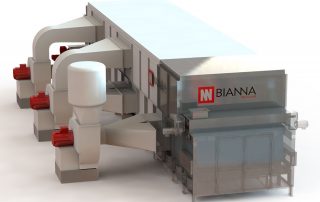

Belt dryer

A key equipment for drying materials using a conveyor belt with adaptable parameters that monitor and ensure optimized adjustment of product drying for maximum profitability.

ThermoValue Solutions designs, manufactures and installs belt dryers that adapt to different processes, materials and humidity ranges. All of them have a series of elements in common: conveyor belt, simple or indirect heating with steam, cross currents, etc.

BDR equipment has the following characteristics:

• Screw motorized feeding system to ensure correct distribution at the inlet.

• Bands of specific* plastic materials for drying (*depending on material to dry data).

• Direct traction for smooth tracks.

• Capture of particles at the gas outlet.

• Material extraction system at the product outlet with humidity controls.

Bianna offers a series of belt dryers with different widths, lengths and thicknesses of belt. All these points are designed keeping focus on the application of the equipment. Moreover, depends on thermal power direct or indirect, cross or parallel flow of drying gases, kind of material to dry and the amount of moisture to evaporate from the income feed.

Our teams have the latest security systems and accesses specifically designed to facilitate cleaning and maintenance tasks.