Multilayer Packaging Recovery

Thermovalue solutions takes a further step towards the circular economy by focusing on the profitability of the process through aluminum valorization, an element quoted in the market for its subsequent energy use.

Aluminum is one of the most common but least visible elements in a large number of packages. It is also one of the most difficult to extract. Recycling aluminum is, today, one of the great challenges in the treatment of waste to achieve maximum recovery and, consequently, close the cycle. It is a challenge due to its complexity but a great opportunity due to its high profitability.

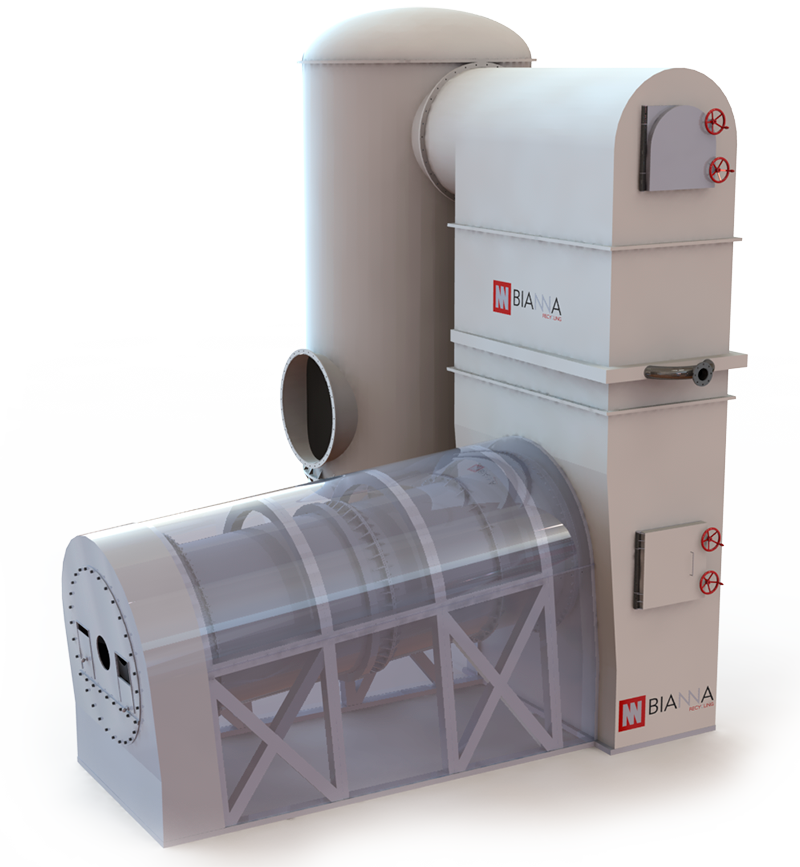

Bianna has developed a technology capable of recovering all the material associated with aluminum in commercial presentations (tetra pack, blisters, etc.) and it’s cracking for its subsequent energy use. The process, integrated into the ThermoValue Solutions systems, is based on a pyrolytic combustion system at low temperature and with a controlled absence of oxygen followed by post-combustion at 1,300 degrees.

An MPR treatment line translates into high profitability: the economic value of aluminum in international markets continues with the climbing path. This reason justifies the whole system.

It is a process integrated into the circular economy: the public administration has made a fundamental commitment to the inclusion of processes for the economic recovery of waste.

Advantages

This system extracts a high quality raw material that allows its direct reintroduction into production processes. Main advantages are:

- Compact equipment with a high level of modularity

- Limited space required for implantation

- Low level of maintenance of the line (in most of its components).

- The excess thermal energy generated can be used directly in other processes such as drying / dehydration, hot water generation and others.