Waste, energy, raw materials and how to make the most of them. Getting circularity right.

On an industrial and individual level, we generate tonnes of waste every day, which can end up in landfills or recycling systems. We now know the scale of the generation, but are we really making the most of the management of this waste?

How much waste do we produce and how much is recyclable?

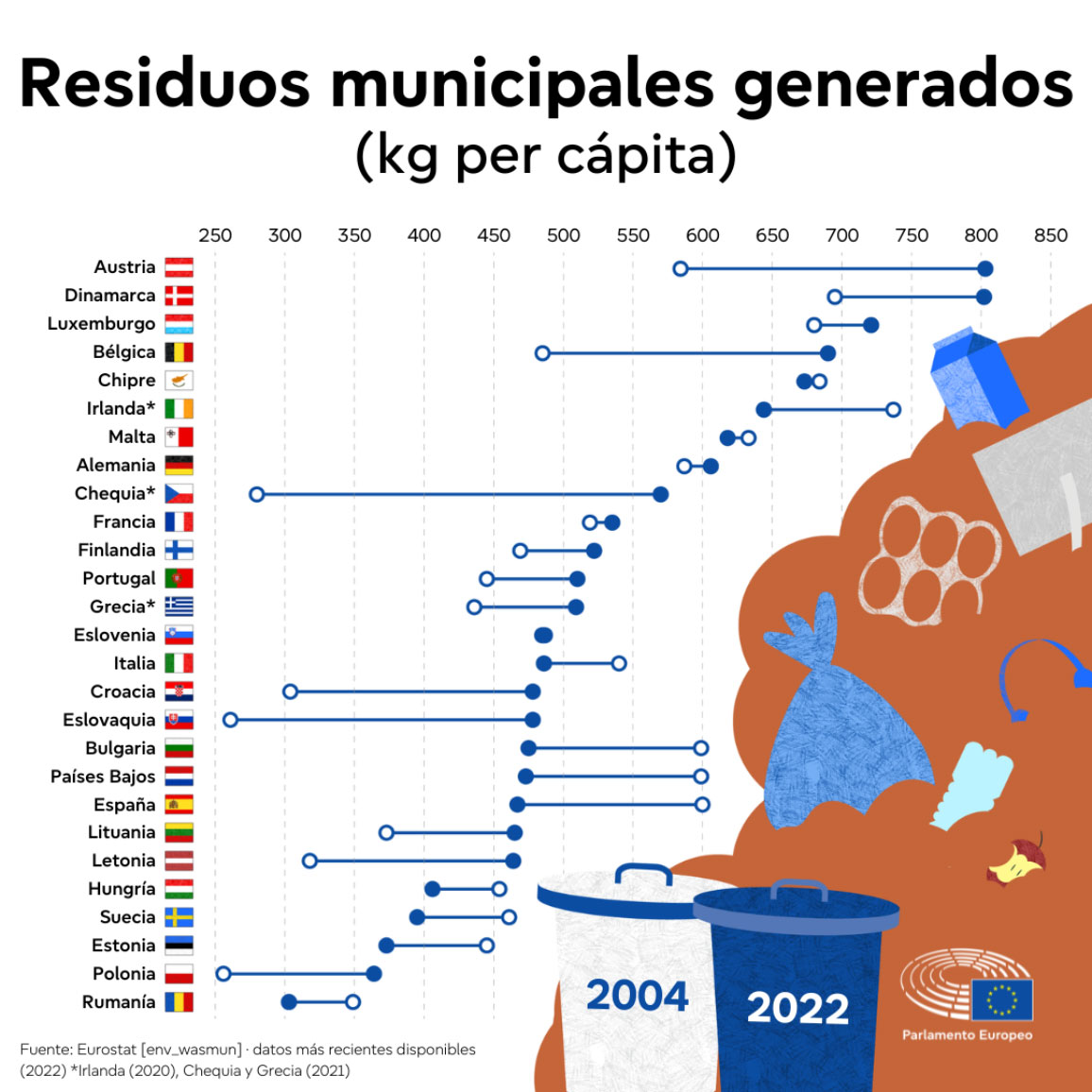

According to information from Eurostat (according to various studies, an average household generates between 1 and 2 kg of waste per person per day), in the case of Spain, in 2022 we will have a production of 487 kg/inhabitant per year (this is equivalent to a generation of between 1 and 2 kg of waste per person per day).

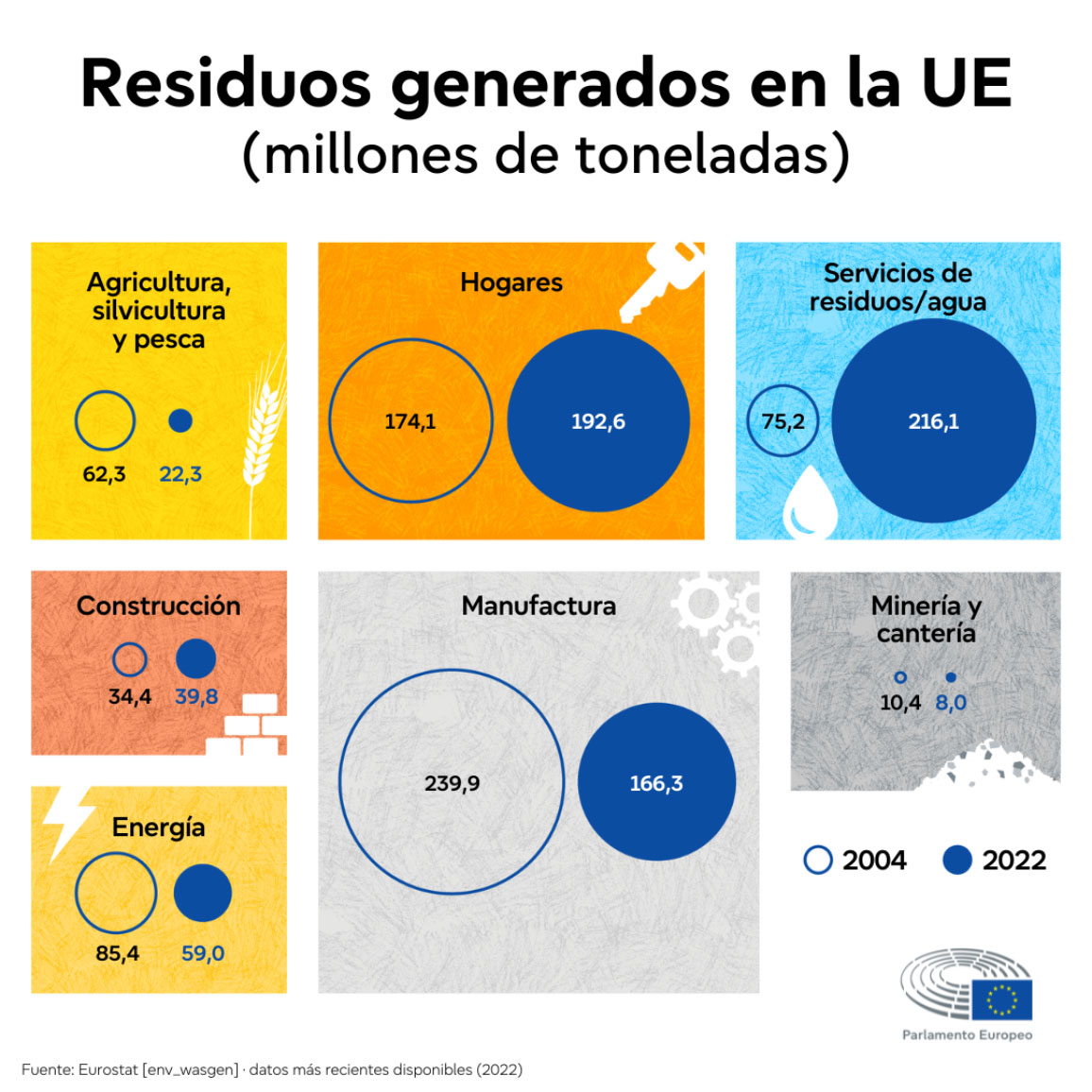

On the other hand, companies produce tonnes of waste each year, depending on the sector.

According to the latest data published by the Instituto Nacional de Estadística, the distribution is as follows:

This waste can be divided into three main groups:

- Industrial organic waste (agricultural by-products, waste from the food industry, sewage sludge, etc.): These are a great source of biomass and can be used to produce biogas or compost.

- Recyclable inorganic waste (metals, plastics, paper, cardboard, glass): These are highly recoverable through recycling and reuse, contributing to the circular economy.

- Non-recyclable or hazardous waste (chemical waste, solvents, waste oils, contaminated materials): Some can be converted into refuse-derived fuel (RDF), while others require specialised treatment. A significant proportion of this is recoverable, either through recycling or energy recovery.

From waste to fuel: Is it possible?

There are several ways to convert waste into energy:

- Biogas: When organic waste decomposes in the absence of oxygen, it produces methane, a gas that can be used as a fuel to generate electricity or heat.

- Energy conversion: Some non-recyclable waste can be burned in energy recovery facilities to produce electricity and heat. However, this practice must be carried out under strict controls to avoid polluting emissions.

- Refuse Derived Fuels (RDF): Some wastes, such as certain plastics, paper, cardboard, wood and textiles, can be converted into fuels for use in cement plants and other industries.

- Conversion into new materials: There are materials (mainly polyolefins) that can be converted back into their primary forms by chemical processes for use as hydrocarbons or as chemical bases for the manufacture of new plastic products.

What waste can be recycled?

Not all waste can be used for energy recovery. Hazardous waste such as batteries, chemical products or certain plastics containing pollutants need special treatment.

There are sectoral plans to achieve a circular economy in Europe by 2050, distinguishing the main ways of working, such as:

- Plastics

- Textiles

- Electronics and ICT

For all these sectors, specific solutions need to be applied that offer a high level of profitability.

For businesses, efficient waste management is not only an environmental responsibility but also an economic opportunity. Implementing recovery strategies can reduce operating costs, minimise environmental impact and contribute to a more sustainable economy.

At present, a high proportion of waste is still sent to landfill:

The key is to optimise segregation processes, promote reuse and work with waste management facilities that maximise energy recovery. Ultimately, industrial waste can cease to be a problem and become a valuable resource.

At Bianna, we work on valorisation in the different ways that current technology allows, in addition to working year after year on the development of advances that increase this valorisation capacity.

Within the framework of a circular economy model, we design and integrate specific energy or material valorisation lines to produce thermal-electrical energy or to obtain new raw materials that guarantee the circularity of the process.

We have a global vision of the process and the management pathways. At the same time, however, we maintain a holistic vision, i.e. each situation requires a unique approach. A company may only need to separate materials to increase its economic value in the market. But for the same material flow, another company may require energy production that ensures (or minimises) its exposure to fluctuating energy values in today’s markets.

From analysis to implementation of the solution, to fulfil our vision: to be a reference company in the design, manufacture and implementation of waste management solutions.